Today me and John originally planned to visit the Nissan Oppama car assembly plant because it was a public holiday, the Emperor's Birthday on December 23. I had phoned a couple of days in advance and was surprised that I didn’t have to book in 2 weeks advance like the Toyota plant in Nagoya. They even sent me detailed instructions on how to get there.

The Nissan Oppama plant was located near Yokosuka which was located about 40 minutes south of Yokohama by train and from our dormitory in Arakawa-ku in Tokyo, it took about 1 hour and 30 minutes to get to the station nearest the plant.

View 2005-12-23: Yokosuka, Japan in a larger map

Once we got there, the Nissan representatives (all young woman) were there to greet us, as well it seemed like they also hired an English translator for us because she was not in their uniforms. I found it so generous that they would do this for only 2 people! Also there was a bus there to take us around the plant.

This is what the reception area of the plant looked like while we were waiting for the tour to start.

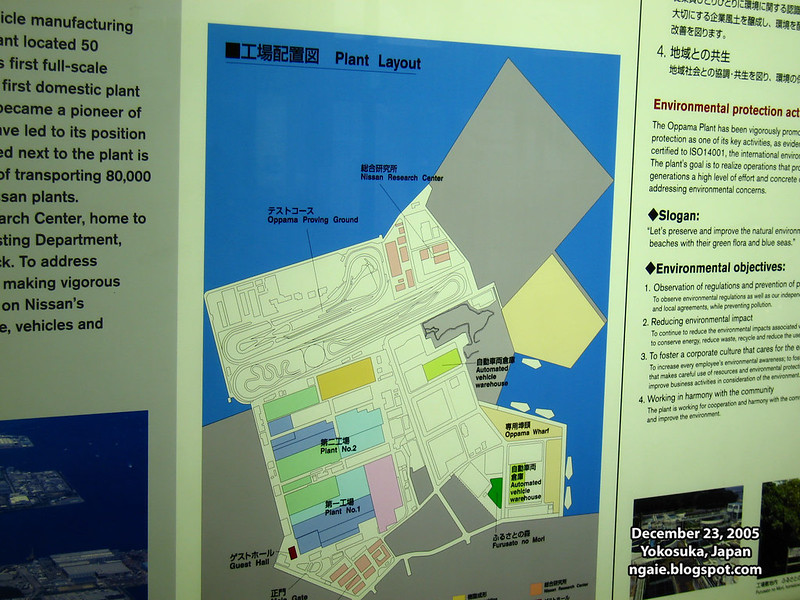

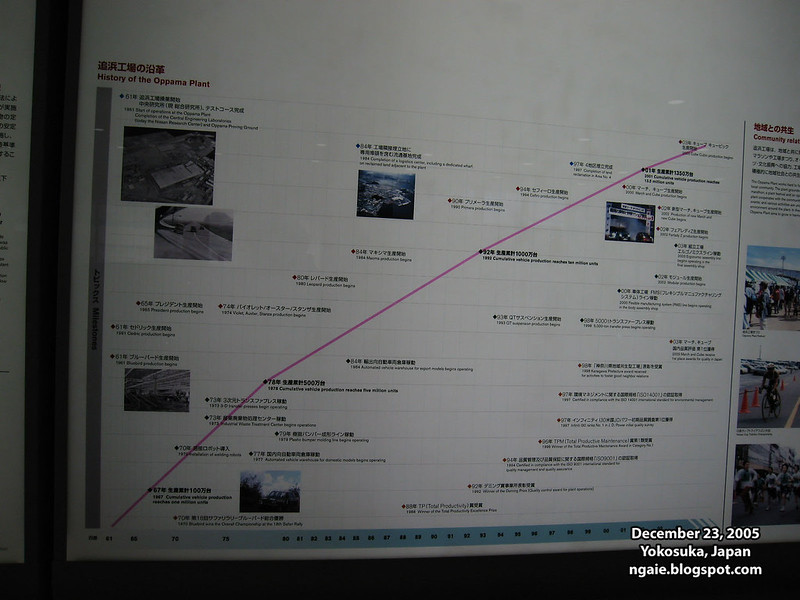

Information about the plant and Nissan.

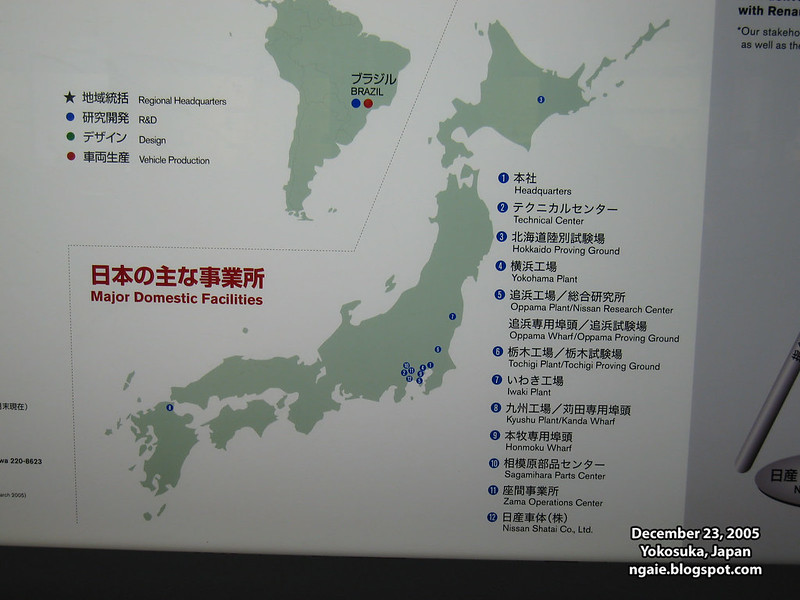

Nissan plants in Japan and around the world.

Q&A with regards to car manufacturing.

Lineup of the models that they made at this plant.

First we went to the wharf to see all the cars that where finished and ready to be shipped off to different places. There were so many cars there but we were not allowed to take pictures of certain areas of the plant. There were row after row of Infiniti cars being readied to be driven onto the ship. Also I learned that Nissan imports Renault cars, approximately 400 and modifies them at the plant. I don’t know who would buy any those cars because they looked like the cars used to transport handicap people.

On the bus to the wharf from the visitor's centre.

Next we went to Assembly Plant No. 1. Unfortunately, no pictures were allowed so I can only describe what I saw in the following paragraphs. If you want to see it, you have to come and visit the plant in person!

We actually got to get off the bus and walked through the real working factory. It was so clean and tidy for a factory (unlike a certain warehouse where I worked in the summer...). First we got the see automatic welding robots in action, it was so amazing seeing this is person, also on the assembly line, there were not just 1 type of car being made but 4 types. The cars we saw being made are only for sale in Japan.

Next we got to see people doing manual assembly. They were assembling the back windshield. We were so close to them, maybe only a couple of meters away from their actual work environment. We couldn’t see them panting the cars because that has to be done in a dust free environment. Next we saw them installing the cockpit module, ie. the console in front seats of the car. They had large machines to easily bring over the parts. They said everything in the plant was designed for efficiency and for workers comfort to avoid bending. They also said the workers tasks rotates every 4 hours so they don’t get bored on the job. Everything in the plant is designed for workers comfort. For example the moving assembly line “walkway” is made of wood panels instead of steel because wood acts like a shock absorber and causes less tension for the workers joints.

Lastly we saw the final production line and how they tested the cars. Workers would go in the car and drive in on a “treadmill” at speeds above 100km/hr to test things. They told us they had to test about 300 things. Also the time it takes to build a Nissan car is 16 hours.

After that we went back to the Guest Hall where they served us hot tea. They even offered to use the company bus to bus us back to the train station, because we had to take the public bus to get there. I was really surprised at how well they organized the tours and treated the guests.

Next we went to Yokosuka because it was close by and home to the US Navy base in Japan and we thought maybe we could get in and see how its like.

The area around the Nissan Oppama Assembly Plant.

Waiting for the train to Yokosuka.

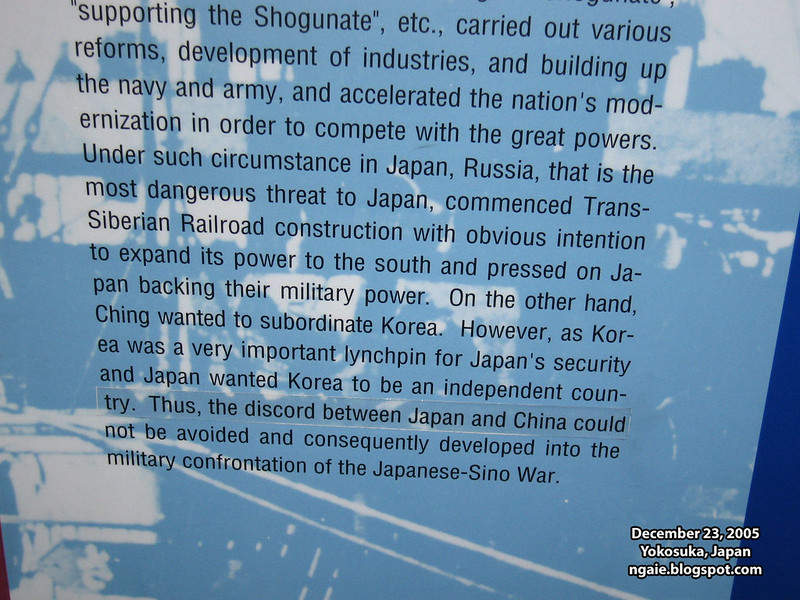

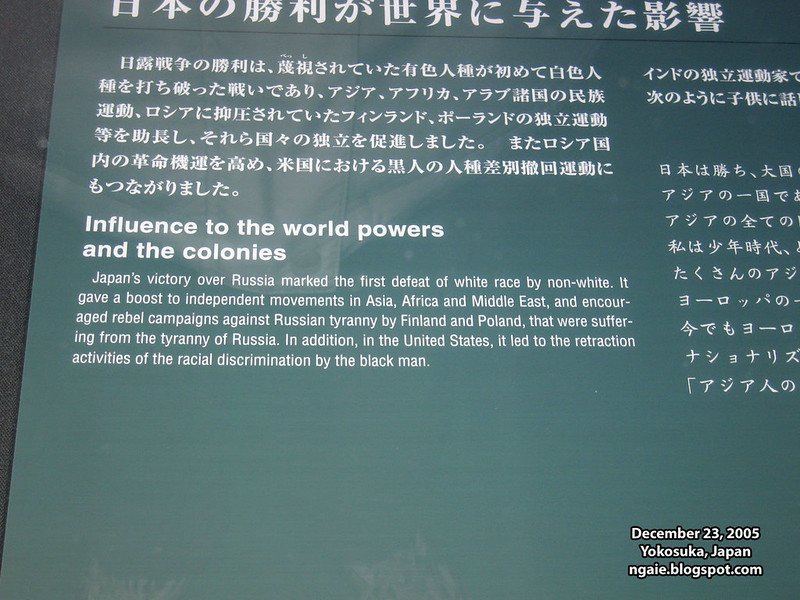

We found the base but after talking to many navy people walking out, only people who were sponsored by someone in the navy could get a visitor’s 1 day pass to visit. We couldn’t find anyone going in so we walked east and saw an old battleship on display as a museum so we went there. The admission price was 500 yen, and inside there information displays that shows “Japan’s version of history”.

From the old battleship.

The US Navy Yokosuka Base in the distance.

The front of the ship.

The back of the ship.

"Japan's version of history" inside the battleship.

This was my favorite information board.

Old locomotive near the battleship museum.

After that we went back to the base entrance to try to find someone that could take us in. Eventually we found someone, a guy from Wisconsin who agreed to sign us up for 1 day visitor’s pass under his responsibility. I didn’t think that we would find anyone to help us get in.

Inside the base, he gave us a great tour of the place. We walked by the Kitty Hawk aircraft carrier that was based at Yokosuka, and he even showed us around the ship he was with. We got on the ship and saw places like the cafeteria, sleeping areas and even got on the deck of ship, I think it was a destroyer. The sleeping quarters basically consisted of a “bed shelf”, “bunk bed” the height between the bunks was maybe less than a meter high. Everyone had a locker to store things and the bed opened to store clothes and other stuff under the bed. After that he took us to the Navy Exchange which was basically an American style store, sort of like Fred Meyer and all the prices were in U.S. dollars, and this is in Japan. Only military people can shop at this store and it had basically everything available in the US. Also there were tons of fast food chains like Taco Bell that don’t exist in Japan but only on this base. Also everything was in US dollars.

The Kitty Hawk aircraft carrier. This thing was huge.

The many ships docked inside the base.

On the deck of the USS Blue Ridge. This was the ship that our friend from Wisconsin was assigned to.

Looking at the Kitty Hawk.

Weapons aboard the USS Blue Ridge.

The base was basically a mini-America inside Japan. In front of that Navy Exchange store was a small parking lot and nothing in the base was cramped. Also the base also felt so American because there were so many black, Hispanic and white people there. It was very interesting that all the people who worked at the shops on base were Filipino.

4 comments:

Pretty interesting, and finally get to see pictures of yourself. Glad to see that you are doing well.

Wow, that's very generous of the Nissan Assembly Plant. They gave you a tour for free!! I thought tours are only given to people to strengthen their business position. Mmmm, I wonder what will happen if I do the same in Canada? think they will probably ignore me.

It's just too bad you can't take more pictures of plant during assembly. Otherwise it's going to be neat to see.

DaYvid

Yay! pics of yourself! Incredible to find out that they did so much just for two gaijins. And I'm glad to hear you still remember your "favorite" workplace.

And isn't Yokosuka the place that Josh from "Josh in Japan" is assigned to? That's pretty cool!

did they think you 2 were north american high rollers for the reason they they got a translater?

but sounded like fun.

your pictures are quite dark. you look skinnier. you should take a pic of ur friend too.

its good that ur in pictures now

but now we have to work on the smiling and makin u look like ur enjoyin the trip

hehehehe

sn

Post a Comment